Strong, reliable, and cost-effective, metal wire ties are an excellent solution for a range of bundling projects. From organizing cables and tightening bags to holding valuable items together, these ties offer superior strength, durability, and ease of use.

Galvanized steel wire, a form of metal enhanced with a zinc shield to prevent deterioration, is the foundation for metal wire ties. The wires are crafted into distinct shapes – from barely-there zip ties to bulky, robust versions – depending on the specific type needed. An array of sizes and structures are provided for every application allowing these ties to be efficient and reliable for long-term use.

Metal wire ties are an indispensable tool in keeping cables and wires neat and orderly. With their impressive strength and flexible nature, they are ideal for binding a variety of materials together securely – even tightly in more confined spaces. These wires are used to fasten strands onto walls, floors, or ceilings, and they can be found in a wide range of industrial as well as commercial settings.

If you need to secure items such as bags and packages, metal wire ties are an excellent choice. They are sturdy enough to stand up to attempted tampering, plus they are simple to adjust to fit the size of whatever you are securing. Furthermore, they come in different colors, allowing you to clearly label and identify the various items. In other words, metal wire ties offer an extra layer of protection that is both easy to use and eye-catching.

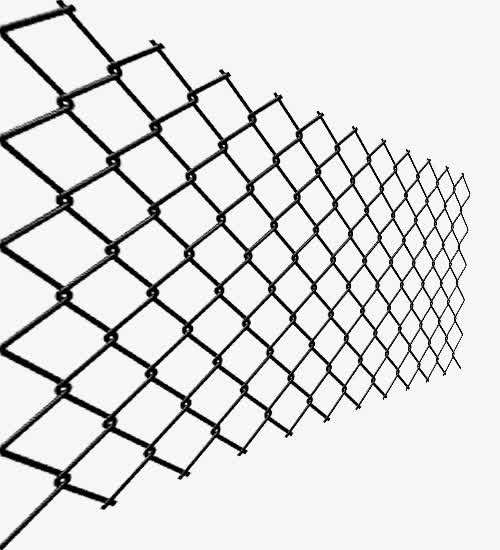

Metal wire ties are essential for construction and landscape projects. They are the ideal tool to bind fencing, posts, and other materials in outdoor settings, as they are both strong enough and flexible enough to withstand any environmental conditions. Not only can they be utilized to fasten artificial objects like posts, but they can also be used to securely attach plants, shrubs, trees, and other flora, ensuring their stability until they are fully established.

Metal wire ties provide dependable, multi-functional support for a range of purposes. Their robust structure and convenient utilization make these ties an optimal selection for bunching wires, fixing items, and arranging components. Furthermore, these accessories are cost-effective and applicable in numerous settings – from corporate to communal to household.

Metal Wire Ties: Essential for Any Organization’s Success

The importance of metal wire ties in a range of industries today cannot be overlooked. From automotive and aerospace to farming, electronics and defense, these necessities are a key factor in how these businesses accomplish their goals. This article delves into the various ways that metal wires ties enhance efficiency, the materials they contrive from and the processes taken to manufacture them.

A sturdy, dependable go-to when connecting two pieces or fastening items, metal wire ties employ a wire loop to bind things like cables, hoses, pipes and sheets. Highly useful and user-friendly, metal wire ties have become a prevalent solution among many organizations seeking to simplify their processes.

For a reliable fastening solution that doesn’t break the bank, metal wire ties come top of the heap. Constructed from robust, highly-resistant materials, these ties possess an impressive tensile strength dependent on size and material. Not to mention, they are simple to install, withstanding even the toughest outdoor conditions – ideal for industry use. In short, metal wire ties bring solid strength at a competitive price.

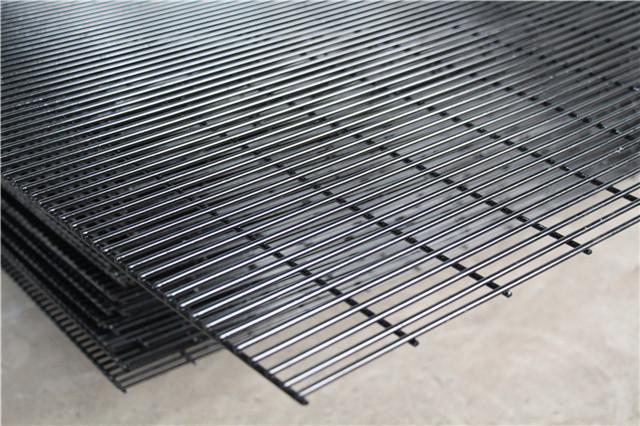

A wide selection of metal wire ties is available in diverse shapes and sizes, from common circles to more unique triangular and recta

Working with metal wire ties requires a precision-driven manufacturing process. The first step consists of cutting the wire to a certain length and forming it into a particular shape. Then, the wire is wrapped around the other material and held together by a metal crimp or wire tie. Crafted from metals such as steel or brass, the crimp adds extra strength to guarantee a secure connection.

To complete the metal wire tie, a protective layer is layered over it. This could be a powder covering, a fresh coat of paint, or perhaps a metal plating that’s suitable for the particular application. This coating acts as a shield to guard the metal tie from corrosion and any other destructive elements. This layer not only extends its life but also bolsters the quality of the final product.

Metal wire ties have solidified their presence in organizations, given their many benefits – they are sturdy and corrosion-resistant, and simple to install. When one takes the price, and variety of sizes and shapes on offer into account, it’s easy to see why metal wire ties have become a go-to workplace staple. It seems their usage will remain essential for many organizations to come.

Related Product

PVC Coated Wire

PVC coated wire, also called plastic coated wire, after high temperature dissolution cooled solid PVC particles uniformly wrapped in high-quality black iron wire and galvanized wi […]

Double Loop Tie Wire

Double loop tie wire material Product Information: Wire diam. 0.5mm—2.0mm Finishes Black Annealed. Galvanized Annealed, Coppered, PVC coated, Stainless steel Wire gauge BWG6 […]

Cutting Wire

Product Description: Product Name Cutting Wire Zinc Coating 30-70g Place of Origin Chinese mainland Tensile Strength 33-50kg/mm2 Material Electro galvanizedHot dipped galvan […]

Black Annealed Wire

Product Description: Product name Black Annealed Wire MOQ: No Material Q195,Q235 Delivery time: 20days after payment Surface annealed or as your request Payment terms: T/T,L/C We […]

Tie Wire

Production Process of rebar tie wire : Steel rod coil — Wire Drawing — Wire Annealing–Rust Removing–Acid Washing– Boiling– Drying– Zinc Feeding– Wire Coiling. Wires Type 1.Galvaniz […]

Galvanized Wire

Product information: Product Name Galvanized Wire Package 5kgs/roll, pp film inside and hassian cloth outside or pp woven bag outside 25kgs/roll, pp film inside and hassian […]

Reel Wire Tool

Product information: Specification of Aluminum Tie Wire Reel Material Plastic & Aluminum Weight 1.95LBS Application Binding Wire MOQ 1000pcs Sample Free Package 5PCS/CARTON &nb […]

Twister Tool

Handle Twister tool,plastic handle: Weight: 0.4kg Color: Black, blue,yellow ,red etc Material: Carbon Steel Plastic Handle Wire Tie / Tying Hook Tool Twister Wooden Handle […]

Garden Wire

Product information: The garden shingling is made of pvc plastic and high-quality galvanized iron wire, which is 3 to 4 times faster than any material, and the buckle is loose, the […]

Post time: 2023-07-21