To complete any concrete pouring venture, remesh and tie wire are essential elements. Without their inclusion, this requisite process would not come to fruition.

For a reliable and well-structured concrete composition, there are two prevalent components in play – concrete pouring remesh and tie wire. The former is a sheet or grid made of metallic mesh, used to further enhance the structural integrity of the concrete. Following this, the mesh is connected and held in place with the help of tie wire. Together, these two components form the foundation of an enduring and robust concrete construction.

Steel-crafted and assorted in a selection of sizes and forms, the remesh is placed atop concrete prior to the pour. It mounts the concrete and gives further durability to the design. One of the most customary remesh measures is four inches by eight inches.

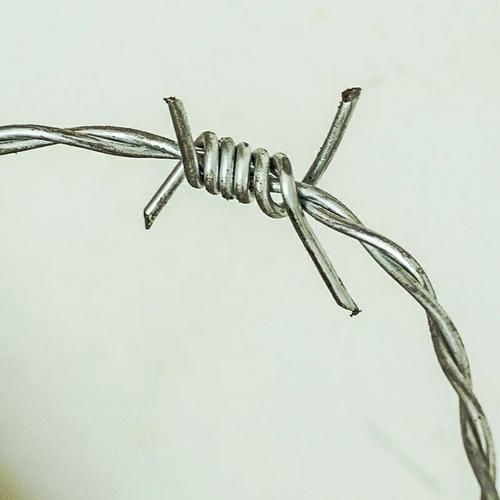

The tie wire is used to lock the remesh securely to the concrete, usually constructed of galvanized steel and wrung together in tight knots. With the assistance of a hammer and nails, these firmly joined loops are kept in place around the remesh and concrete for a guaranteed bond.

The strength and durability of any concrete pour are bolstered by the essential inclusion of remesh and tie wire. Each plays an important role, securing the structure and providing a supporting backbone for the concrete to rest upon. Without them, no structure of this kind could remain solid.

During the remesh and tie wire setup process, it is vital to guarantee that the mesh is fixed securely and that the wire is sufficiently tied around the remesh plus the concrete. If the wire is not rightly secured, it can lead to a fragile structure and shortened durability.

Not only does remesh and tie wire contribute to the fortitude and resilience of a structure, but it can add an artistic feel and style. The mesh helps develop a decorative motif or creates a unique texture for the concrete. And, the wire can be employed to infuse a splash of vibrancy and complexity in the structure.

In the end, concrete projects rely heavily on the use of both pouring remesh and tie wire. These components assure any edifice is fortified and reliable, locking in the foundation and providing greater longevity. They also beautify the construction with patterns, textures, colors, and contrast; extending any structure’s aesthetic appeal.

Whether reinforcing foundations, driveways, patios, or other concrete projects, pouring remesh and tie wire are crucial ingredients of the construction trade. Together, these two components help provide the extra support needed to bolster the strength and longevity of concrete elements. Admittedly challenging to install properly, when done right, they are essential for raising the quality of any concrete construct.

To construct a firm superstructure, driving rain or windproofing buildings, Remesh is an appropriate solution. The mesh is reinforced steel wire fixedly arranged in grids, lined on the concrete surface before pouring. Acting as an amalgamative fortress, the strengthened material sports a rust-resistant coating to bolster durability. Securely grounded, a protective tie wire is woven around the mesh for preservation and stopping any relocating during the pouring procedure.

To ensure steadiness during the concrete-pouring process, tie wire is employed to bind the remesh together. Composed of galvanized steel with a corrosion-resistant finish, it forms into a loop and fastens around the remesh. By doing so, it safeguards the stability of the remesh and upholds its position as the concrete is poured.

Proper installation of remesh and tie wire is integral to the construction of any concrete reinforcement project. Orientation must be correct and all wire should be sufficiently tightened to maintain placement throughout the pour. If neglected, mesh can become undone and consequently weaken the anticipated overall strength of the concrete.

When undertaking a project, selecting the correct size and grade of remesh is essential. With the sheer number of high-quality varieties to choose from, it can be a daunting decision. Additionally, taking into account the structure’s orientation when installing the mesh is key in not only maintaining an ideal level of durability but assuring that stability remains intact throughout the concrete-pouring process. Proper tie wire placement also makes a significant difference in guaranteeing a robust outcome.

Before the concrete takes its shape, it is essential to take a look at the remesh and tie wire to ascertain that they are put up correctly and are still in sound shape. Furthermore, scanning the area is important to make sure that no sharp edges or elements are present which could harm the mesh and tie wire while the mixture is being poured.

After the concrete is put in place, it is essential to inspect the mesh and tie wire to make sure they are still intact. If there is any wear or tear, it should be fixed or exchanged so that the reinforcement will be robust and efficacious.

In the construction world, concrete pouring remesh and tie wire offer a powerful solution for reinforcing projects. Proper installation and use can boost the strength of any concrete endeavor, resulting in a high-quality final product. Inspecting the mesh and tie wire before and after pouring concrete is consequently vital for achieving the desired results.

Related Product

Twister Tool

Handle Twister tool,plastic handle: Weight: 0.4kg Color: Black, blue,yellow ,red etc Material: Carbon Steel Plastic Handle Wire Tie / Tying Hook Tool Twister Wooden Handle […]

U Type Wire

Product information: Product Name Scaffolding Packing Galvanized Tie Wire Cuttings U Type Binding Wire Material Electro galvanized,hot dipped galvanized,black annealed,PVC coated W […]

PVC Coated Wire

PVC coated wire, also called plastic coated wire, after high temperature dissolution cooled solid PVC particles uniformly wrapped in high-quality black iron wire and galvanized wi […]

Double Loop Tie Wire

Double loop tie wire material Product Information: Wire diam. 0.5mm—2.0mm Finishes Black Annealed. Galvanized Annealed, Coppered, PVC coated, Stainless steel Wire gauge BWG6 […]

Reel Wire Tool

Product information: Specification of Aluminum Tie Wire Reel Material Plastic & Aluminum Weight 1.95LBS Application Binding Wire MOQ 1000pcs Sample Free Package 5PCS/CARTON &nb […]

Tie Wire

Production Process of rebar tie wire : Steel rod coil — Wire Drawing — Wire Annealing–Rust Removing–Acid Washing– Boiling– Drying– Zinc Feeding– Wire Coiling. Wires Type 1.Galvaniz […]

Black Annealed Wire

Product Description: Product name Black Annealed Wire MOQ: No Material Q195,Q235 Delivery time: 20days after payment Surface annealed or as your request Payment terms: T/T,L/C We […]

Garden Wire

Product information: The garden shingling is made of pvc plastic and high-quality galvanized iron wire, which is 3 to 4 times faster than any material, and the buckle is loose, the […]

Galvanized Wire

Product information: Product Name Galvanized Wire Package 5kgs/roll, pp film inside and hassian cloth outside or pp woven bag outside 25kgs/roll, pp film inside and hassian […]

Post time: 2023-07-22